INDUSTRIAL AND MINING ELECTRICIANS

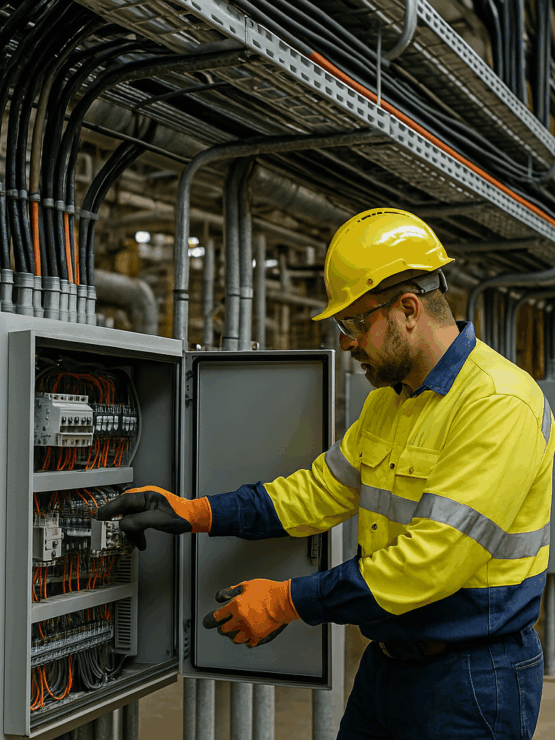

Power Control Industries supports industrial and mining sites across Mackay, Isaac, and regional basins. Our team delivers high-voltage and complex solutions to meet demanding site requirements.

We focus on compliance, performance, and minimising costly downtime for every client.

SPECIALIST ELECTRICAL SERVICES FOR

INDUSTRIAL AND MINING ENVIRONMENTS

In high-risk environments, there’s no margin for error. Power Control Industries delivers technically advanced, compliance-driven electrical solutions designed for the demands of industrial and mining operations across regional Queensland, including Mackay to the Whitsundays, Sarina to Moranbah.

Our licensed electricians are experienced in heavy industry, high-voltage systems and mission-critical infrastructure. We prioritise proactive maintenance, automation-ready systems and regulatory compliance to reduce unplanned downtime, support site safety and keep complex industrial systems running without interruption.

Explore our full range of industrial and mining electrical services below.

High-Voltage and Complex Electrical Installations

High-voltage systems in mining and industrial sites demand absolute precision and reliability. Our licensed electricians design, build and commission compliant installations for high-load environments where safety, continuity and compliance cannot be compromised.

We deliver infrastructure that performs under pressure, meets Australian Standards and reduces the risk of failure across critical systems.

Capabilities include:

- High-voltage cabling and certified terminations

- Substation construction and switchroom fit-outs

- Transformer installation and integration

- Grid connection and compliance assurance

- System testing, fault protection and live commissioning

INDUSTRIAL AUTOMATION & PROCESS CONTROL

Improve site efficiency and reduce manual errors with intelligent automation systems designed for industrial and mining environments.

We integrate control technologies that support precision, safety, and long-term scalability, tailored to your operation’s unique processes.

Capabilities include:

- PLC programming & upgrades

- SCADA system integration

- Process instrumentation

- Motor control systems

- Panel builds & I/O wiring

- Troubleshooting & optimisation

COMMUNICATION AND

DATA CABLING

We design and install structured cabling systems for commercial sites, delivering fast, reliable network performance across all devices and departments. From high-speed data points to WiFi access points and server racks, we install future-ready systems that support IT upgrades, secure data flow, and scalable growth.

Ideal for office fit-outs, multi-site operations, and growing businesses that rely on always-on connectivity.

Capabilities include:

- Structured cabling design and installation

- Voice and data outlets for office networks

- Patch panels, racks, and switching hardware

- Fibre optic and Cat 6/6A data cabling

- Enterprise WiFi coverage planning

- Cabling upgrades for NBN and IT infrastructure rollouts

24/7 EMERGENCY

SERVICING

When site-critical systems fail, the cost is more than downtime. It impacts safety, compliance and production. Our 24/7 emergency servicing delivers fast fault response across mining and industrial sites where continuity is essential.

We work within shutdown protocols and emergency tier procedures, with guaranteed response times backed by active service agreements and ongoing system monitoring.

Capabilities include:

- 24/7 callout support for site-critical electrical faults

- After-hours and weekend response for unplanned issues

- Guaranteed response time frames backed by active agreements

- Fault isolation, emergency repairs and temporary restoration

- System health checks and RCD testing

- Monitoring and reporting for audit or compliance purposes

INDUSTRIAL AND MINING ELECTRICAL WIRING SOLUTIONS

General-purpose wiring won’t cut it in mining and industrial operations. We design and deliver infrastructure that performs under harsh industrial loads, environmental stress, and compliance-critical conditions.

Our licensed team works to AS/NZS 3000 standards, tailoring every solution to your site’s power requirements and future expansion.

Capabilities include:

- Submain circuit installation and upgrades

- Three-phase outlets and high-bay/floodlight systems

- Rewiring and infrastructure load balancing

- Weatherproof and rodent-resistant cabling

- Dedicated wiring for plant, machinery, and safety systems

- Power for HVAC and industrial exhaust systems

- Electrical solutions for sheds, workshops, and multi-site operations

PREVENTIVE CONTRACT MAINTENANCE

Safeguard site uptime and protect critical infrastructure with structured preventive maintenance tailored for industrial and mining demands. Our service plans support operational continuity, asset integrity, and compliance with AS/NZS standards, all delivered under isolation controls and scheduled shutdown conditions.

We customise each contract to match your site’s load requirements, risk exposure, and audit expectations — keeping your systems safe, compliant, and operating without disruption.

Capabilities include:

- Monthly, quarterly, or annual maintenance programs

- Thermal imaging and fault detection for HV systems

- Switchboard, protection, and safety system testing

- Site-wide compliance reporting (AS/NZS 3000, 3017)

- Asset condition audits and lifecycle assessments

- Maintenance support for plant, workshops, and heavy machinery

THERMAL IMAGING &

FAULT DETECTION

Reduce downtime risk and safeguard plant infrastructure with site-specific thermal imaging inspections. Our infrared scanning technology identifies hotspots, abnormal current draws and early-stage faults in switchboards, sub-mains, cable runs and motor control centres.

These non-contact inspections are fast, safe and compliance-ready. They help prevent insulation breakdown, reduce unplanned failures and support predictive maintenance across critical assets.

Capabilities include:

- Detection of heat-stressed switchboards, terminations and cable joints

- Infrared scanning of sub-mains, cable trays and MCCs

- Identification of current imbalances and developing equipment faults

- Compliance reporting aligned with AS/NZS 3018 standards

- Insurance or audit-grade reporting for asset tracking

- Integration with scheduled or shutdown maintenance programs

BACKUP POWER SUPPLY

SOLUTIONS

Ensure critical systems perform through power loss with backup solutions engineered for mining and industrial sites. We supply and install uninterruptible power supply (UPS) systems, generators and automatic transfer systems designed to meet high-load demands and maintain continuity under pressure.

Each solution is tailored to your site’s infrastructure and risk profile, with full support for installation, integration, compliance testing and ongoing maintenance.

Capabilities include:

- UPS and generator supply, installation and commissioning

- Load profiling and site-specific backup design

- Automatic transfer switch (ATS) installation and programming

- Load testing and compliance reporting

- Backup integration for safety systems, critical plant and remote sites

- Planning for shutdown coverage and redundant power systems

INDUSTRIAL AND MINING ELECTRICAL FAQs

Yes. Our electricians hold current Coal Board Medicals, Standard 11, and all required mine site inductions across Queensland. We are certified for confined space, working at heights, and complete site-specific training as needed. Our team regularly support shutdowns, live-site compliance, and remote operations.

Yes. We provide scalable maintenance and servicing contracts for businesses with multiple locations. Our team supports multi-site clients across Mackay, Sarina, Proserpine, Moranbah, Airlie Beach, and other regional centres throughout Queensland. Services are tailored to ensure consistency, compliance, and minimal disruption across every site.

Yes. We provide all necessary reports, tagging records, testing results, and compliance documentation aligned with Australian Standards.

We offer guaranteed response times under service agreements. For remote sites, we work with your team to pre-stage access and integrate with existing shutdown protocols.

We assess site loads, risk categories, environmental hazards, and compliance requirements before designing any high-voltage system. Our solutions meet AS/NZS standards and are engineered for continuity in harsh conditions.

PowerControl Industries is committed to environmental stewardship.We implement sustainable practices in our electrical installations and maintenance services, aiming to minimise environmental impact and comply with all environmental regulations.

We work as part of multi-trade teams during shutdowns and project rollouts. Our supervisors are experienced in sequencing works, following site-wide safety plans, and collaborating with site engineers and project managers to maintain timelines.

At PowerControl Industries, we adhere strictly to all relevant safety standards and regulations for mining operations. Our team undergoes regular training to stay updated on the latest safety protocols, ensuring a safe working environment and compliance with industry requirements.

Yes. In addition to plant installations, we provide electrical solutions for site-wide infrastructure including admin buildings, camp facilities, haul roads, and communications.