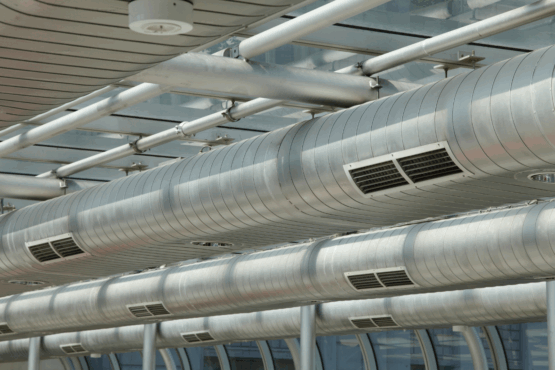

Industrial Air Conditioning

Power Control Industries delivers a full range of industrial and mining air conditioning services across Queensland’s key regions, including Mackay, Sarina, Moranbah, the Whitsundays, Bowen Basin and Galilee Basin.

Reliable Industrial Air Conditioning Services In

Mackay, Whitsundays, Isaac, and the Bowen Basin.

At Power Control Industries, we provide specialist Industrial Air Conditioning solutions across Mackay, the Whitsundays, and regional Queensland. Whether you operate a manufacturing facility, warehouse, data centre, or large commercial site, we design, install, and maintain systems built for performance and reliability in harsh environments.

Our team understands the unique demands of industrial-scale cooling, from heavy-duty ventilation to precision-controlled air for sensitive equipment. We work with leading commercial-grade brands to ensure every system is energy-efficient, compliant, and fit for purpose.

Engineered HVAC Systems for Industrial & Mining Sites

Power Control Industries designs and delivers fully engineered HVAC systems for mining and industrial environments.

We work with builders, developers, and operations managers from planning through to installation. Every system is tailored for airflow efficiency, load demand, and long-term durability, backed by CAD documentation, zoning plans, and compliance with Section J of the NCC and Australian Standards.

Installations are carefully scheduled to minimise disruption, with after-hours and shutdown-ready options across the Bowen and Galilee Basins. Each project includes handover documentation for compliance and auditing.

All systems are installed by ARCtick licensed technicians and QBCC certified contractors, with ongoing support available beyond commissioning.

Services available:

- HVAC system design and technical specification

- Equipment selection based on load, zoning, and energy targets

- Load calculations, ducting design, and airflow mapping

- CAD documentation for approvals and quotes

- Ducted, split, and VRF/VRV system installations

- Mine-spec HVAC for crib rooms, containers, and site offices

- Installation scheduling for shutdowns or after-hours delivery

- BMS-ready system design and control planning

- Compliance-aligned design with Section J and Australian Standards

Industrial & Mining Air Conditioning Repairs & Maintenance

When systems fail or performance drops, fast, qualified support makes all the difference. Power Control Industries provides HVAC maintenance and repairs built around your schedule and site access needs.

We work with maintenance planners and site supervisors to deliver servicing and urgent repairs for HVAC systems in crib rooms, site offices, warehouses, and mobile facilities.

Our team supports sites across the Mackay region, Moranbah, and the Bowen and Galilee Basins, reducing downtime, extending unit lifespan, and keeping your site audit-ready.

Services available:

- Maintenance scheduling matched to site hours or shutdown timelines

- Emergency repair support with same-day response across key regions

- Leak detection, refrigerant top-ups and pressure calibration

- Filter replacement and airflow optimisation

- Service logs and documentation for compliance and reporting

Industrial Unit Upgrades & Retrofits

In complex or cost-sensitive environments, full HVAC replacement may not be an option. Power Control Industries delivers retrofit solutions that maximise system performance, prolong equipment life, and help you avoid compliance delays without the disruption of major system change.

Specialists in retrofitting legacy VRF, ducted and split systems commonly found in mine camps, hospitals and industrial infrastructure that need performance restored without full replacement.

Our approach is tailored to your floorplan, usage profile and operational priorities, helping you reduce energy consumption, meet audit standards and avoid unnecessary replacement costs.

Services available:

- System assessments and performance benchmarking

- Energy-efficient component upgrades

- Zoning and airflow balancing

- Smart control integration and BMS compatibility

- Ductwork modifications for improved efficiency

- Compliance re-commissioning and supporting documentation

Industrial Air Conditioning Unit Replacements

Avoid compliance failures, mounting energy costs and unexpected breakdowns by replacing underperforming HVAC systems with site-ready solutions built for remote and high-demand environments.

Power Control Industries replaces legacy ducted, VRF and split systems across mine sites, FIFO accommodation, healthcare buildings and industrial infrastructure. Our team assesses your site layout, energy load and operating demands to recommend a system that meets your performance and compliance targets.

We manage safe removal, environmentally compliant disposal and installation with minimal disruption to your team or schedule.

Services available:

- Full site assessments and system performance reviews

- Replacement of legacy or underperforming HVAC systems

- Equipment selection based on zone usage and load requirements

- Safe removal and environmental disposal of old systems

- Installation, testing, commissioning and shutdown-aligned scheduling

- Post-installation servicing plans and warranty documentation

Emergency HVAC Repairs for Industrial & Mining Sites

A sudden cooling failure can halt operations, endanger staff, and trigger costly compliance issues.

Power Control Industries delivers fast-response HVAC repair services across mine sites, FIFO camps, processing facilities and industrial infrastructure. Our licensed, site-inducted technicians are shutdown-ready and skilled in diagnosing and repairing complex system faults with minimal disruption.

Service agreement clients receive 24/7 priority support, along with detailed response reporting for audits and compliance tracking.

Protect uptime and compliance with rapid-response HVAC repair. Enquire Now for priority service access.

Services available:

- 24/7 emergency HVAC response for service agreement clients

- Rapid on-site diagnostics for split, ducted and VRF systems

- Repairs for cooling outages in crib rooms, containers and electrical spaces

- Temporary cooling deployment to stabilise critical site areas

- Compliance-focused reporting and incident documentation

- Priority scheduling and follow-up maintenance planning

Air Conditioning System Inspections & Assessments

Identifying faults early and reduce unplanned downtime with targeted HVAC inspections.

Power Control Industries conducts preventative assessments across industrial, healthcare, and mining environments to improve performance, reduce energy waste, and support audit readiness.

Our team inspects refrigerant systems, airflow restrictions, electrical components and mechanical wear in high-demand spaces like hospitals, site offices and processing areas.

Each inspection includes a compliance-focused report with practical recommendations aligned to your site hours, maintenance cycles or shutdown schedule. Fewer surprises, longer equipment life, and less pressure on your operations team.

Services available:

- Full system inspections and performance assessments

- Leak detection and refrigerant pressure checks

- Ducting and airflow testing

- Motor and electrical component analysis

- Risk identification and early fault detection

- Audit-ready inspection documentation and planning

Indoor Air Quality Testing & Improvement Services

Poor air quality can reduce productivity, increase health risks, and compromise compliance — especially in enclosed industrial spaces and remote mining facilities.

Power Control Industries delivers full-service indoor air quality (IAQ) assessments to reduce airborne contaminants and optimise HVAC performance. Audits measure ventilation, humidity, and pollutant levels, with reporting aligned to AS/NZS 3666 and 1851 standards.

We provide tailored recommendations and system upgrades for high-traffic sites, accommodation blocks, switch rooms, and process building, helping you protect your team and strengthen operational resilience.

IAQ should be assessed annually, or more frequently in high-risk or high-occupancy sites.

Services available:

- Indoor air quality audits aligned with AS/NZS 3666 & 1851

- VOC, CO₂, and particulate testing in enclosed workspaces

- Ventilation and airflow performance analysis

- HVAC-integrated purification system design and installation

- On-demand testing or scheduled IAQ monitoring contracts

- Site-specific strategies for FIFO camps, healthcare sites and multi-tenant industrial buildings

Energy Efficiency Upgrades, Air Balancing & Zoning

Improve comfort, reduce unplanned outages, and support audit performance with targeted HVAC upgrades across industrial and mining sites.

Power Control Industries provides energy audits and upgrade solutions for remote mine camps, healthcare environments, and industrial facilities across regional Queensland. We identify airflow loss, zoning issues, and system inefficiencies, then implement tailored solutions to reduce energy waste and extend system life.

Our technicians deliver airflow balancing and zoning upgrades for consistent climate control in high-traffic work zones, crib rooms, and temperature-sensitive areas, including automated scheduling, VRF multi-zone setup, and smart thermostat integration.

For more guidance, visit the Energy Rating website to compare energy-efficient models.

Services available:

- HVAC energy audits and efficiency benchmarking

- Airflow loss detection and duct leakage testing

- Energy-efficient zoning systems and zone recalibration

- Smart zoning installation including VRF multi-zone scheduling

- Energy-efficient equipment upgrades and specification

- BMS and EMS integration for site-wide control

- HVAC energy monitoring and compliance reporting

- Sustainability support for energy targets and audit readiness

Ductwork Installation & Repairs

Airflow loss and energy waste often start where no one looks, the ducting.

Power Control Industries delivers precision ductwork solutions that improve HVAC performance, reduce operating costs, and support compliance across industrial facilities and mine sites. Our upgrades restore airflow balance, improve zone control, and help you stay audit-ready.

Our technicians assess airflow, system layout, insulation, and zoning before repairing or installing ducting to AS 4254 standards. Where needed, we integrate automated dampers, airflow sensors, and modular ducting systems for staged builds or shutdown-based scheduling.

Services available:

- Industrial ductwork design and installation

- Commercial duct leak detection, pressure testing, and recommissioning

- Repairs and upgrades for damaged or legacy ducting

- Airflow balancing and system performance optimisation

- Insulation and sealing to reduce energy loss

- Compliance inspections and service logging

- Audit-ready ductwork documentation and reporting (on request)

Industrial & Mining Air Conditioning FAQs

Zoning allows for more precise climate control across separate areas of your site. Whether you’re running offices, production areas, or crib rooms, zoning helps you manage comfort more efficiently while lowering energy use and reducing strain on the system.

Air balancing ensures each area receives the correct airflow. This reduces temperature fluctuations, helps equipment work more efficiently, and extends system life, especially important in large, multi-zone facilities.

In mining environments, dust and particulate build up in ductwork can quickly compromise air quality and system efficiency. Regular inspections and servicing help prevent performance drop-offs and maintain safe working conditions, especially in remote or enclosed areas.

An energy audit involves a full system assessment, including airflow checks, equipment performance, insulation, and zoning. The goal is to uncover areas of waste and recommend solutions that align with compliance, sustainability, and operational goals.

Smart thermostats allow for programmable temperature scheduling, remote access, and zone-specific controls. These systems help reduce unnecessary energy use and give facility managers greater visibility over how HVAC systems are performing across the sites.

Unusual noises, poor airflow, fluctuating temperatures, or unexplained energy spikes are all signs your system may need servicing. Regular checks help catch small issues before they lead to system failures. If you're unsure, our technicians can assess your current system and provide honest, Contact our team to discuss your needs and receive tailored advice.

In mining and remote industrial environments, HVAC system failure can disrupt workflow, affect safety, and delay production. 24/7 support ensures you're not left waiting until the next business day when cooling or ventilation issues arise. Contact our team to discuss an emergency response service for your site.

BMS (Building Management Systems) and EMS (Energy Management Systems) provide centralised control and real-time data on HVAC usage. This helps optimise performance, detect issues early, and track energy consumption, especially useful for meeting sustainability reporting standards.

Absolutely. Energy-efficient equipment, better insulation, zoning upgrades, and improved airflow can significantly reduce your carbon output. These upgrades not only help reduce operating costs but also support compliance with internal or government-led environmental targets.

Mining sites often face harsh weather, dust exposure, and limited maintenance windows. Systems need to be robust, low-maintenance, and easily serviceable. Proper design, regular servicing, and accessible parts availability all play a role in keeping systems running smoothly in remote conditions.

Most industrial systems should be inspected at least twice a year. However, high-demand sites or those in extreme environments may benefit from quarterly servicing to ensure reliability and compliance with safety and performance standards.

Indoor air quality affects worker wellbeing, system performance, and compliance, especially in sites where people spend long periods indoors or rely on controlled environments.

In aged care and healthcare, poor air quality can contribute to respiratory issues and infection spread. In industrial and mining settings, it can lead to equipment strain, dust-related health risks, and increased energy costs. Indoor air quality should be assessed at least annually, or more frequently in high-risk or high-occupancy sites.